As you might expect, we have had a huge number of calls and emails over the last couple of days regarding external wall insulation. It was with great sadness that we all witnessed the events at Grenfell Tower, in North West London – our deepest sympathies are with all those involved.

It is clear that much of the media have already begun to blame the rainscreen cladding system as a contributing factor to the accelerated spread of the fire. Obviously, a full investigation will have to take place before we know for sure, but it certainly looks like this may have been the case.

We feel it is important to educate people on this type of cladding system. Rainscreen cladding is a solution that is primarily designed to protect a building from the elements. It tends to be made up of a protective, decorative outer coat attached to the underlying structure of the building by a supporting grid (metal frame in many cases). The cavity created between the outer cladding and the building structure is often used to house insulation materials, but also it maintains a ventilated cavity, and aids draining. The cavity between the insulation and the protective cladding is normally a minimum of 25mm.

These rainscreen cladding systems can be either retrofitted to existing buildings or incorporated into new builds.

Often rainscreen systems are hybrid systems based on architects’ requirements to improve both the look and thermal performance of a building. They therefore take advantage of materials from different companies to provide the desired effect.

External Wall Insulation (EWI) is not rainscreen cladding

External wall insulation on properties is very different – in the majority of cases this is retrofitted to the property to improve the thermal performance of the property while also giving it an aesthetic facelift. The materials used in external wall insulation are specifically designed to work together to produce the desired effect – they normally all come from the same manufacturer.

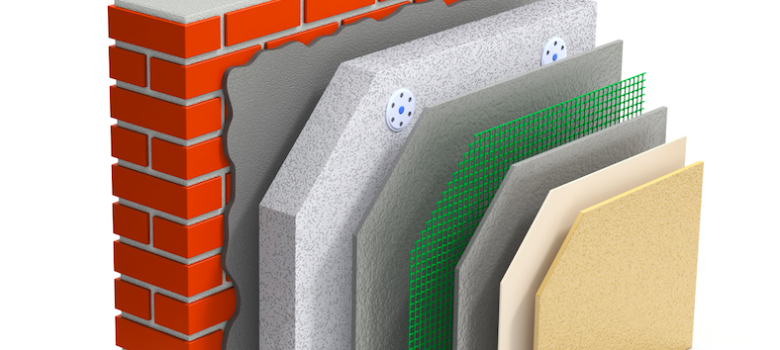

Basically, an insulation board is ‘glued’ to the wall using cement based plaster adhesive. Mechanical fixings then tie the insulation board to the wall. On top of this another layer of cement based plaster is added and a fibreglass mesh is sunk into the plaster while it is still wet. Finally, a top coat render is added to the system to give the desired finish – this can be any colour and also comes in a huge range of different finishes. Our understanding from speaking with a few external wall insulation manufacturers is that the insulation material is fully enclosed within base rails and the cement based finish from the external elevation of the property.

External Wall Insulation is a regulated market

The external wall insulation industry is a heavily regulated industry in the UK. Independent bodies such as the British Board of Agrement (BBA) and KIWA-BDA are notified bodies and UKAS approved to independently test and certify external wall insulation systems so they meet the rigours of the building regulations here in the UK. As part of this independent testing, the systems are tested against a number of elements including: water absorption, wind loading and combustibility.

In addition to the manufacturers or system designers, the installers themselves doing the works may also be accredited with the PAS2030 or an equivalent quality management system. While these certification and procedural elements don’t necessarily guarantee the quality of the final installation, you can rest assured that those installers will be monitored and rigorously audited on the works that they do. Monitoring bodies who enforce the PAS2030 certification have the power to kick off bad installers to keep the standards in the industry high.

Finally, it is also worth mentioning that on bigger projects, like a retrofit of multi-storey properties or a number of properties within an area, the system designers will also send their technical teams to provide additional monitoring of the installers to make sure they are getting installed as they have been designed on the system specification and the BBA certificate. The installers themselves should also (via the manufacturers) provide maintenance advice post installation that helps maintain the system safely and securely during its lifespan.

Mineral wool and stone wool are classified as non-combustible

The insulation material itself tends to be either made from mineral wool or EPS. Mineral wool offers substantial protection against fire since it is non-combustible (Euroclass A1). Regardless it is enclosed within a layer of concrete adhesive, so the structural integrity of the system would remain intact even if there was a fire.

With regards to EPS, it is an organic compound so it would burn in much the same way as wood or paper if fire came into contact with it (it would actually melt first). In the case of EPS used in external wall systems, it tends to include a flame retardant such as polymerised bromide to help decrease its flammability.

EPS is fully enclosed within the external wall finish

If there was a fire in the property, EPS would melt within its cement-based plaster enclosure, but the mechanical fixings would support and hold the structure of the EWI in place. So, while after the fire, an EPS external wall insulation would need to be stripped and replaced it should not act as a fire accelerator.

External Wall Insulation industry post-2017

As mentioned we are extremely saddened by the events at Grenfell Tower, but we feel it is important the mainstream media do not scare the hundreds of thousands of people who have had solid wall insulation installed on their properties over the last few years. Therefore, we must allow the independent enquiry to take place, which will allow the evidence to be gathered and hopefully form conclusions about this incident, leading to even more robust standards in future across the building industry.

Dear Sirs, I have signed a contract to get my property insulated with the insylated renders. Silicone render finish using the JuB system. Am I at risk or is this whole thing overblown?

Hi Viral, the system you mention there has the BBA certification both on the EPS and the Mineral Wool insulation systems. See the link to the BBA website: http://www.bbacerts.co.uk/CertificateFiles/49/4955ps1i2.pdf which is the example of the EPS EWI System. As long as the installer installs the system correctly and then the system is subsequently looked after by yourself, then you shouldn’t have any issues.

The BBA is a paid for service to regulate the industry and despite manufacturers outside the UK going through every test and specification for Europe and world sales, the BBA insist that products are re-tested at very high costs and annual fees to remain approved. Despite being a part of the EEC ( until now) this has been allowed to continue. Typically British Standard states that the Final surface finish on EWI does not require BBA approval, but this is never discussed. My point is that approval of each component does not mean the systems are fitted correctly or customers are given all the options available.

Will the whole country be a sea of white rendered houses, and just how many issues will come out of th e woodwork as with cavity insulation sold by the Double Glazing Direct Sales fraternity.

Hi Viral, That should be absolutely fine – the JuB system is very good. Basically the rainscreen cladding is specified by architects to do a number of jobs – in this case improve thermal efficiency (due to the addition of insulation), improve the look of the building and also protect it against the elements. With this in mind the architect normally specs a whole range of different products that come together as a hybrid system to fulfill their requirement. In this case they opted for PIR board (un covered), plus a void plus a flammable plastic outer rainscreen.

The jub system, much like other external wall insulation systems basically involve sticking insulation board to the wall, covering it in a layer of cement based plaster and then putting a render on top. The insulation board is completely enclosed in cement adhesive. There is no cavity that can cause the chimney effect. All parts of the system are manufactured by the same company and are designed to work in perfect harmony together.

Basically the media is really sending out a confusing message.

EWI is different from Rainscreen cladding – and EWI is completely safe. Rainscreen cladding can also be completely safe provided the materials selected are appropriate.

Hi reading this has me horrified , not by you but the standard of work done by the green deal contractors expanded foam used in gaps under sills up too 3 ins thick gaps between slabs of insulation overfills fitted after insulation done silicone put on in pouring rain ,no officials looking at back of houses I can go on and on ….the worst example was a curtain of mesh covered with polyfesin render and pebbledash therefore leaving the polystyrene exposed near gas meter

Hi Mr Fagan, I think unfortunately that is endemic of the grants that were offered. Installers who had previously installed other measures (e.g. loft insulation / cavity wall insulation) jumped on the EWI bandwagon as they felt they could make a quick buck, despite having no experience in installing it previously. I think the key (and this is not helpful for yourself having already had the work done) is to get an installer in who specialises in EWI. We have a network of installers who fall into this category, so you can always ping us an email or give us a ring. Likewise if someone has had the works done and they are happy with their installer, go with their recommendation – recommendations are normally the best way of getting a tradesmen!

Found this on the insulation product used:

On 14 June 2017, a fire broke out in Grenfell Tower, a block of flats in North Kensington, London. The fire spread up the outside of the Tower unexpectedly quickly, and initially, suspicion focussed on the Reynobond PE ACM cladding rainscreen panels. However, on 23 June 2017, the Police confirmed that small-scale fire tests had been carried out on the Reynobond ACM cladding and the Celotex insulation and both had failed.

Detective Superintendent Fiona McCormack said; “The insulation was more flammable than the cladding. Tests show the insulation samples combusted soon after the test started.”

Basically if you have Celotex on your home you should be probably get it removed….

External wall insulation is a target that Energy Generators have been set under the Energy Company Obligation Order 2014. (now amended). This includes a requirement to install ‘measures’ in the homes of the ‘fuel poor’ in ‘social housing’. I am afraid that there is an element of this tragedy that is directly attributable to Govt ‘environmental ‘targets’. The demonstrably beneficial and cost effective schemes have been largely used up in preceding scheme (loft insulation). PIR and similar insulation is preferred to rock wool as it delivers more CO2 saving per mm, and the composite aluminium panels similarly score higher on BREEAM assessments etc than a non combustible alternative. BBA receives UKAS accreditation through a memo of understanding with the Dept of Business, Environment and Industrial Strategy, as opposed to the dept of Communities and Local govt which is responsible for the Building regs. There is no effective regulation as the regulatory sector has no clear guidance, as is semi privatised. The green sector is in danger in being completely subsumed by commercial interests and priorities.

We have old 1930s semi detached 3bedroom house and would like some out side wall insulation information to put on the side of our property we own the said property.We live in north west Manchester M8 5AG

Any material that is nor wholly non-combustible, or adds any calorific value to a fire, or causes failure through delamination should be banned on any building over 12m in the UK. Our current test regime was always unfit for purpose (as it did not allow for Wind driven fire heat energy release rates) I’ve seen ESP (with a simple surface cement skim) used on tower blocks in Kent. This will be an unfightable fire if it becomes involved. The Green movement, who jumped into bed with the Plastics industry, has a lot to answer for (in relation to high rise accommodation)