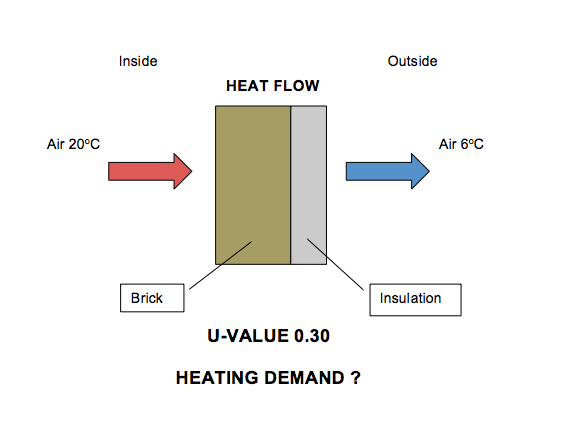

Demystifying U-values and their effect on the heating demand of your house

In this article we are going to figure out the effect of U-values on the heating demand of your home. By adding insulation to the walls of your home, you reduce the U-value and in turn you will save money on your…

2015 Climate Change Conference in Paris

The 2015 United Nations Climate Change Conference (COP 21 or CMP 11) was held in Paris, France, from 30 November to 12 December 2015. It was the 21st yearly session of the Conference of the Parties (COP) to the 1992…

How much energy does my home use?

Estimating how much energy a home uses Domestic buildings are responsible for 30-40% of primary energy use in the UK. When talking about primary energy use, we tend to be referring to electricity and gas, although some properties use oil…

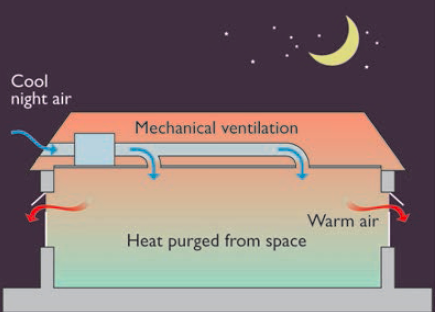

Mechanical ventilation in buildings – what you need to know

How do we deal with hot weather in the UK or getting rid of latent warm air without spending huge amounts of energy and money on air-conditioning systems? Although natural ventilation is the commonly low-cost practice to cool a building efficiently…