Who are Climeworks?

Climeworks are a Swiss company that have developed the technology to suck carbon dioxide out of the air and convert it from a harmful waste product and into a commercial resource. The company then works by selling this processed CO2 on to a variety of industries, helping bring down existing carbon dioxide levels while creating a valuable material.

How do Climeworks plants work?

The idea that Climeworks have found a solution to global warming is a pretty remarkable one. After all, if they can just remove the carbon dioxide from the air then what are we all still worrying for? How is this possible and what is the technology behind it?

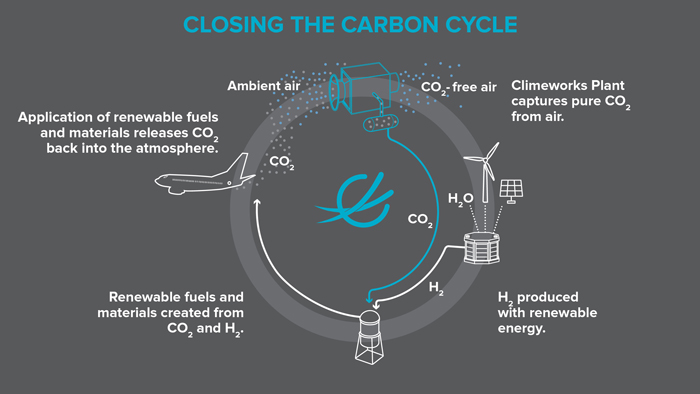

The system works by passing the air through two stages:

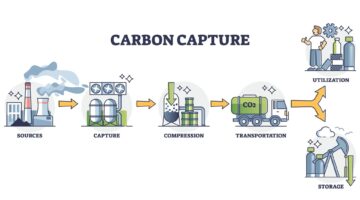

Stage 1: Capture. During the first stage the CO2 binds to a filter, while the rest of the CO2-free air is released back into the atmosphere.

Stage 2: Containment. The second stages takes the CO2 that was chemically bound to the filter, and heats the entire thing to 100C. This process collects the waste materials and compresses them into purified, useable CO2. This can then be stored, or used for commercial purposes.

What does Climeworks do with the CO2? / Where does the CO2 go after being removed?

After the carbon dioxide has been removed and compressed into a useable resource, it can be utilised in a few different ways. The gas can be sent to a greenhouse via an underground pipeline, pumping the purified gas to a greenhouse containing vegetables such as tomatoes and cucumbers, enriching them by 20% due to the carbon CO2 boosting the photosynthesis process. Alternatively, it can be used for commercial purposes, such as being sold to beverage companies for carbonising fizzy drinks.

Why are Climeworks different?

Climeworks are the only company that is using geoengineering to remove the already emitted CO2 from the atmosphere.

Even if we stopped emitting carbon dioxide today, or shifted to a low-carbon economy, it is unlikely to be enough to prevent the process that we’ve already started. Climeworks are bucking the trend of preventative measures that could well be too little too late, and are instead focusing on fixing the damage already done.

Is it effective?

The Climeworks operation is designed to be powered primarily by a waste heat recovery system located onsite or close by to the plant. This is a renewable energy source, to ensure that the company is not causing any sort of pollution.

Climeworks have issued a goal to capture 1% of the world’s CO2 emissions by 2025; a number that may sound small but is in fact an enormously ambitious target. The company claims that they would need 250,000 DAC (direct air capture) plants to be able to work towards/achieve this.

The biggest problem is cost. Although the process sounds fairly simple, in actuality it’s incredibly complicated and extremely costly. The estimated system total cost could be as much as £760 per ton of CO2.

Climeworks are working hard to overcome this, having recently have raised around £30 million towards the project. These funds will be used to industrialise their technology and significantly reduce their costs in a bid to make widespread use of the technology feasible.

Making it a viable commercial option, with the aim to eventually create something convenient and readily available for widespread mainstream use, is the company’s current end goal.

by Jordana Allen-Rowlandson

Think we missed something? Do you have a different opinion?

Comment below to get your voice heard…

No Comments yet! Be the first one.