What is CCS algal synthesis?

Bio CCS algal synthesis is a new process in which the carbon cycle that normally takes millions of years can be reproduced on an Algal synthesiser in 24 hours. It is the latest in a long line of potential Carbon Capture and Storage technologies, although it is more focused on the capture of carbon dioxide and turning it into a useful product rather than simply CO2 storage.

MBD Energy Limited and an algal research team from James Cook University have developed a 5000m2 test facility designed to produce 14,000 litres of oil and 25,000kg of algal meal from every 100 tonnes of CO2 consumed.

How does this form of carbon capture work?

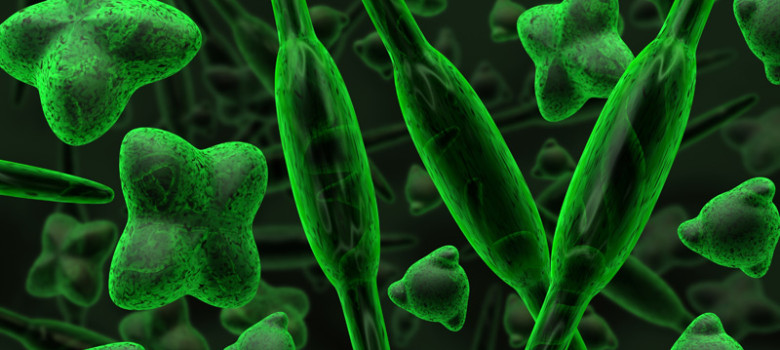

The process of algal synthesis involves injecting captured flue gases (the exhaust gased from burning fossil fuels) into a waste water growth medium infused with locally selected strains of micro algae, contained in an enclosed membrane system. The algae photosynthesise with sunlight, using the CO2 as fuel for growth, doubling its mass every 24 hours causing the waste water to thicken as the growth takes place. The algae is harvested daily and crushed to produce algae oil, algae meal and clean water (35% oil and 65% algae meal). In this manner, the algae capture CO2 that would otherwise find its way directly into the atmosphere, thereby offsetting one of the major greenhouse gases.

What can we use the resulting by-products for?

Biofuels – The algae oil produced as a by-product of carbon CCS method is ideally suited to biofuel production. In addition, the glycerine, which is a secondary by-product of this biofuel production process can be used in such areas as pharmaceuticals, cosmetics and food production. The algae oil also can be used to make plastics.

Feed for livestock – The algae meal that results from CCS algal synthesiser can be used as feed for livestock, The algae meal has an advantage over conventional livestock feed in that there is a lot less cellulose in it, this is because algae is supported in water, where as plants need to support themselves in air so need the cellulose for rigidity. The breakdown of cellulose by the ruminant digestive system causes the release of methane, so low cellulose feed has the benefit of not producing as much methane as a by-product of this reaction.

Biomass – the algae meal can also be used as biomass for fertilizer, bio plastic production and energy production.

MBD Ltd are currently in the process of moving from the test facility to full scale display plants, at a number of Australia’s major coal burning power stations. These ‘proof of concept’ projects that commenced last year take the greenhouse gases from the power stations flue chimneys and produce the oil and the algae meal out of this process.

Benefits

- Compelling sustainable solution to 3 significant world issues: Oil, food and CO2.

- Bio CCS removes CO2 from the air, therefore mitigating one of the gases that is thought to be responsible to Global Warming.

- The Carbon Cycle process, that normally takes millions of years, can take 24 hours.

Limitations

- Commercially harvesting the technological process is still in its infancy – more trials are needed to prove the technology has a worthwhile payback period.

If this technology goes to full commercial production, could we bring this technology to the Philippines? I would be the first one to spearhead the introduction and setting up of a company to introduce the technology to the coal-fired power plant in the Philippines.

Pls reply if you are interested my services.

Thanks and regards,

Richard

Hello mr Lonzaga. I don’t know how interesting this might be for you but we’re a group of bachelor students in environmental science at mid Sweden university, that at this moment are taking a course were we will investigate the possibilities to put this system to use on a large scale. We will work towards a district heat plant that want to install such a system.

We will also present our results at the International Conference on Life Cycle Management, in Bordeaux if our request to do so is accepted.

If you are interested I could speak whit the professor that are in charge of the project about the possibilities for you to take part of our results and about a possible cooperation to put this type of systems to use in the Philippines.

He would probably want to know who you are and what your position are.

Regards Johan.

If interested you could send an e-mail to jojo1218@student.miun.se

Would like to talk with technology developers regarding our consented 300 MW Biomass CHP plant – we are looking at Carbon capture in longrun for Storage/ EOR but could accelerate capture timeline with suitable utilization strategy – rate of capture etc extremely flexible i.e. we can capture anything between 0 and 600000 tons CO2 /a

I am Managing Director of DMCI Holdings, Incorporated, a listed company in the Philippine Stock Exchange.which owns several coal powered plants

Would like to contact MBD Ltd. to discuss how their technology can be accessed.