What are Carbon Dioxide Scrubbers?

In other sections of this site we have covered the concept of carbon capture and storage, which is the process of removing carbon dioxide from entering the atmosphere and storing it. Most of the technologies we have looked at focus on removing the gas where it is developed in high quantities, for example in the exhaust gases produced by coal power stations.

Carbon dioxide is found in the air everywhere though; so why just concentrate on where the gas is emitted in higher quantities?

It is possible to scrub CO2 from the air anywhere; the technology has been around for decades and used on Submarines and Spacecraft, to name but a couple of examples. So the potential is there to research and build on this technology, scaling it up so it can be positioned to effectively scrub the air in any location.

How does CO2 Scrubbing work?

Despite several different designs currently being in development, they all are based on a common chemical reaction. Air is sucked into the machinery where it is bought into contact with a sorbent material which chemically binds with the Carbon Dioxide. A sorbent material is one that simply absorbs a gas or liquid (e.g. sponge is sorbent as it absorbs many times its own weight in water).

The greater the surface area of the sorbent, the more efficiently it will absorb the gas or liquid, therefore different mechanisms have been suggested to maximise exposure of the sorbent to the carbon dioxide, thereby maximising it’s scrubbing ability.

The Palo Alto Research Centre has proposed to draw the CO2 through a fine mist of liquid sorbent. Housing this technology in towers that are several metres high, the mist would react with the gas and be collected in a chamber where they would once again be separated. The pure CO2 could be compressed into liquid form and removed, while the sorbent would be recycled and used again to collect more of the gas.

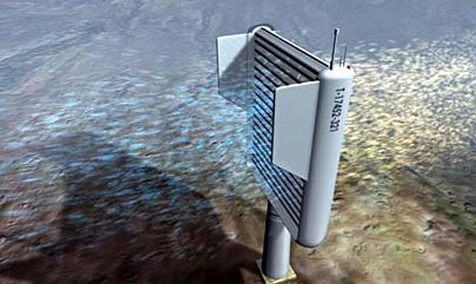

Klaus Lackner, has created another proposal to maximise the surface area of the sorbent, and this to apply solid sorbent to thin sheets and allow the Carbon dioxide to react with it. Once the initial reaction has taken place, liquid chemicals are washed over the sheets that create a stronger bond with the CO2 than the sorbent. The liquid can then be collected (as it now is bound to the CO2), and this can be heated which will allow the CO2 to be stripped from the liquid, and so once again the pure CO2 could be compressed into liquid form and removed, while the liquid can be recycled and used again to wash future CO2 from the sheets.

Issues facing the technology

The air-capture machines are electrically powered, and most electricity produced (via non-recyclable methods) has carbon dioxide emissions associated with it. So an important question is whether the carbon dioxide stripped from the air is in excess of the carbon dioxide ‘produced’ to drive the machine. In fact, Klaus Lackner’s prototype uses 100kwh of electricity to remove 1 tonne of CO2 from the air, and this power required equates to 35kg of CO2 being produced as emissions, so the ratio of gas removed far outweighs the amount produced. In fact, if the energy used to drive it is derived from renewable energy forms then the figures become even more attractive.

Another issue facing the technology is that the sorbent material cannot be recycled for ever, and has a finite lifecycle, after which it has to be replaced so this makes sorbent supply high (and expensive), in addition there will be maintenance costs associated with swapping the sorbent material over. The cost currently associated with removing 1 tonne of CO2 from the atmosphere is about £150 per tonne when using these carbon scrubber methods, while the cost of trading a tonne of carbon is about £6-£13 (see carbon trading). Only when the cost of removing a tonne is lower than the trading cost will this become truly commercially viable. Dr Lackner has suggested that he feels that with technical improvements and economies of scale achievable if the products become commercially successful, then the cost will come down to approximately £30 per tonne. In addition trading carbon prices will rise in the future, as countries looking to fulfil their green promises endeavour to make the cost of emitting CO2 unattractive.

Finally, where do we position the carbon scrubbers? In the grand scheme of things, CO2 present in the atmosphere is found in very low percentages, roughly 0.04% (with 99% made up of Nitrogen and oxygen), so actually removing it out of the atmosphere is difficult. Therefore when we produce the compressed gas as a result of the carbon scrubbing technologies, it is important that we have a use for it. CO2 is a useful gas in it’s own right – it can be used to pump into commercial greenhouses to increase plant growth, it can be used to inject into natural gas reserve beds to drive more of the gas out; It can even be transformed into fuel for transport. So we should erect the carbon scrubbers where the CO2 produced can be then used to perform a useful function. In the future, if the technology takes hold and is profitable (the stored gas can be sold for more than it costs to remove it), then we could see the widespread launch of carbon scrubber ‘orchids’, simply acting to remove the gas from the atmosphere, but until that time it is important that we spend time considering the best places and set ups for these technologies.

dear Supplier,

we have some sort of reaction in our manufacturing facility, which resulted to release of carbon dioxide with 2bar pressure for about 10minutes, we need a scrubber to absorb this carbon rather of letting go direct in environment, please let us know the system if you can help out.

Regards,

Dr Abida

I am designing a modest art installation to highlight the concept of CO2 gas scrubbing. The details here are very relevant.

Hi. What is keeping us from putting CO2 scrubbing devices on the air intake systems of the diesel engines that are moving the millions of big rigs(18 wheelers) that are traveling the highways of the world. Or any big engine air intake for that matter.

Actually Jessy, they’d need to be fitted to the exhaust system as that’s where the CO2 is emitted. In answer you your question I believe that the answer is that nobody knows how to do this yet, certainly not at both the small ‘miniature’ level required to be fitted to vehicles and also it would need to ‘scrub’ at quite a considerable rate.

From what I understand oceans absorb co2 out of the air. Do you have an idea if it would theoretically make more sense to scrub co2 water from the ocean? I can imagine that by extracting it from the ocean water, you’ll increase its absorbtion capacity. And you could use tide changes to power the whole thing. Just a thought.

This was really helpful, next time I would add a picture of what one looks like, and add a diagram o fhow it owrks

Hello! I am a Senior Student in Industrial Design and for my thesis project, I am creating a device that can capture and collect CO2 in the air. My concept is based on amounting the device in a mass transportation system such as trains or cargo ships, this way we can use its movement to generate a constant flow of air into the device. Would love some feedback from this amazing community. Thanks!