When we talk about insulation in lofts, we are usually referring to rock wool or glass fibre insulation. There is another- sometimes overlooked – category of insulation: foil. We know that foil makes a good insulator because of its very highly reflective properties, but does a thin layer of foil actually perform as well as a thick slab of insulation? Is there any way to get those ultra-low U-values required of modern buildings without having a thick layer of rock wool? Let’s take a closer look.

U-value of foil insulation

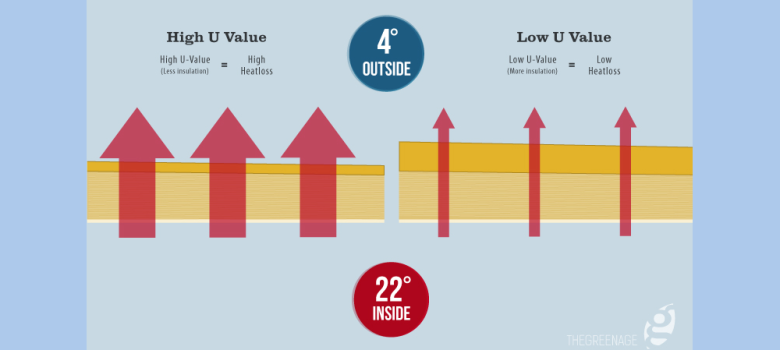

The U-value is a simple measure of how easily heat is able to pass through a material. Lower U-values mean better thermal performance. Most brands of insulation have a U-value displayed on their products as a matter of pride. Typical fibreglass insulation, for example, requires 270mm of insulation to get to a U-value of 0.16. Phenolic board like Celotex or Kingspan requires 175mm or so to achieve 0.16.

If you pick up a pack of foil insulation, the U-value is often not easy to find, if it’s there at all. So what is the U-value of foil?

Radiation vs conduction

Regular insulation works by preventing the conduction of heat through the material. The insulation is tested in a lab to work out the conduction through the material, λ (lambda). This value can be used to work out the U-value for any given width of material.

This works well for most insulation materials, because conduction is the main way they prevent the movement of heat. Foil insulation works slightly differently, however. Whilst there will be some resistance to conduction, thanks to the air gaps between the layers of foil, most of the performance of the material lies in its ability to reflect radiative heat back into the room. This characteristic is not an important player when it comes to fibreglass or wool insulation, but is crucial for foil.

It means that foil insulation is going to have a higher U-value, but may well perform better than expected in the real world. There is not much unbiased data out there to give you on this, but some manufacturers have done real world tests comparing foil with standard insulation, with encouraging results. Obviously, it depends on the type of foil and the amount of layers present, but some evidence suggests a performance better than standard insulation at much reduced thicknesses.

Foil insulation is used by NASA, right?

Foil is used in space-faring craft because of these great properties preventing radiant heat loss. Because space is a vacuum, there is very little heat lost by conduction, so foil is absolutely perfect.

How do I use foil insulation?

Foil insulation is worth considering if you have restricted space in your loft or roof space that means regular insulation is not viable. You will have to ensure there are good air gaps either side of the foil to get the best performance. We would recommend going for one with plenty of layers and some heft to it, as the thinner ones will not give a great performance.

Building regulations and foil

You might wonder – if the U-value is not apparent – whether foil insulation can be used to meet building regulations requirements for insulation. The answer is that it is at the discretion of the planning authority, and each authority will probably treat things differently. Because foil insulation companies will provide their own energy saving data on their product, it is down to the individual planning authority as to whether it can be used and what thickness is required to meet the standard.

Should you use foil insulation?

We would probably recommend shying away from it unless it really is the most practical option, due to space constraints. In this case, speak to your architect and planning authority to find exactly what would be the most suitable thickness.

Think we missed something? Do you have a different opinion?

Comment below to get your voice heard…

so what is the u value of foil insulation? apparently you aren’t in the business of selling stuff but in writing mystery, suspense novellas which leave the true identity of the killer up to the readers imagination. this should really be somewhere in the first paragraph, particularly if you are trying to convince a sceptical, potential customer to not use an alternative, tried and tested product whose manufacturers are willing and able to provide the technical details for.

which specific make and model of foil insulation are you asking about? How many layers and of what composition? Your question needs refining

True dat

For wall insulation I use 10mm horizontal battens on the wall bouble bubble foil on the battens then 10mm vertical battens and then foil backed plasterboard,pleased with the results we now only use two balanced flue gas fires on the ground floor of a three level victorian semi.

Probably too costly if paying someone else to do the work.

Foil reflects radiant heat unlike mineral wool and phenolics which decrease conduction and convection.

For best results use nominal thickness builders foil (shiny side facing warmth) as first layer followed by mineral wool or phenolics.

This gives best of both worlds.

Question for you Mick! I am insulating a bus from scratch, it is down to the metal exterior which is painted. I am having difficulty deciding which side of my insulation to put the foil on, On top of insulation/inside of living space or exterior against the metal bus shell. Exterior heat and cold transfer is both a concern, but primarily keeping the bus cool enough in summer is the biggest concern. However, heat loss through the floor in the winter is a very real problem also. Obviously, I have extreme space constraints of only about 2″ +/- for all the surfaces. Do you recommend metal-foil-insulation or metal-insulation-foil. would it work to be against the metal exterior because I’m thinking that’s the best way to keep the bus cool in the summer? Any help is appreciated.

I suggest you have the panels spray foamed.

Any radiant barrier insulation (eg aluminised foil) needs a air-gap to reflect (radiate) the heat into. It will not work where it touches other materials – like plasterboard, foam, wood, or paint. Such contact prevents any heat radiation, and heat flow becomes conductive or convective.

This article explains it fuller. I am not associated with this company. I am an engineer.

https://atticfoil.com/index.php/about-radiant-barrier/why-is-an-air-space-required/

This seems such an obvious thing to do, I’m wondering why the site hasn’t suggested it. Are there any possible problems associated with this approach?? I’ve tried it as an experiment over just my bathroom and I think it has made a noticeable difference to the comfort of the room – but only did it a week ago, so not had long enough to test it through a range of different external temperatures (the weather has been pretty mild in the week since I did it (December).

I’d really be interested to hear anyone’s feedback who has tried this approach

what

i have no idea what you are saying

I wold like to buy a drought buster bath water syphon but there is a problem getting onto their site. Have they gone out of business?

I put 50mm celotex between rafters and superquilt over rafters. Counter battened and plaster board. Old House but loft is lovely and warm now.

In houses built in 1960 with pitch roofs and attic space will the foil be able to be put down, slide down, unroll so to speak, the sloping spaces from the attic under the root?

My dad had a time tested moto, ” don’t come with a problem unless you have at least one suggestion”. You might want to give your readers a couple of options by naming brand & sizes in foil insulation we should look for to counter the thin foil you don’t recommend. Thx

I am planning an internal wall of insulation but have limited space. I looked at foiland considered a 10 mm static air gap either side of the foi. Would any one like to comment on the effectiveness of this proposal as the foil companies claim there foil can offer an insulation value of 75mm for the equivalent of one layer of their foil.?

Yes but the air gap is crucial. 25mm minimum