According to the planning portal if more than 25% of the solid wall is renovated with solid wall insulation the installation needs to adhere with building regulations. Building regulations stipulate that a solid wall needs to achieve a u-value of 0.3W/m2K or better.

Insulating solid walls to building regulations

For most of us the u-value doesn’t mean an awful lot though – instead it is probably easier to say what thickness of material needs to be used to meet the requirements.

As we have discussed previously there are 3 types of solid wall insulation used in 99% of installs.

- EPS (expanded Polystyrene)

- Mineral wool

- PIR board (e.g. Celotex)

Based on the fact the insulation is being installed on a traditional solid wall property (with a u-value of 2.13W/m2K) – in order to achieve a final u-value of 0.3 Watts / m2K you need to use the following thicknesses.

- EPS – 88.6mm thick

- Mineral Wool – 108.6mm thick

- PIR board – 65.7mm thick

In reality installers won’t insulate down to the millimetre though, most installers of EPS will install 90mm or 100mm. Likewise with the mineral wool installers will go with 110mm thick insulation.

Insulating in restricted space

Now in some cases installing this much insulation simply won’t be possible. Take for example a path between two properties, which puts a limit on the scaffolding width that can be installed between the properties.

>>>Click here to learn more about external solid wall insulation<<<

In this case, where it is not technically or functionally feasible, the official line from the Government is that a wall should be upgraded to the best possible standard, which can be achieved within a simple payback of no greater than 15 years. Now in reality the payback depends on energy usage in the home, so the depth of insulation used can be pretty much up to the discretion of the installer.

Below though we have shown how the u-value varies for the same 3 products if only 50mm of the particular product is used.

- EPS – 0.48 W/m2K

- Mineral wool – 0.56 W/m2K

- PIR – 0.38 W/m2K

Obviously this is some way away from the building regs requirement especially for the mineral wool and EPS, but it is still as good a cavity wall with retrofitted insulation.

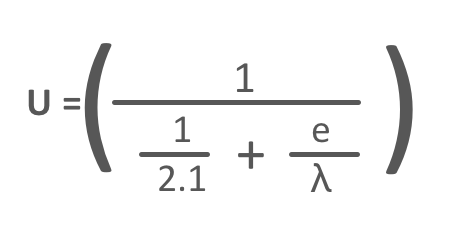

If you have a solid wall insulation project and are looking to see what u-value will be achieved with a given thickness you need to use the following formula

Where:

e = the thickness of insulation in metres

λ = the conductivity of the insulation

2.1 = the u-value of a solid wall

The conductivity of the three different insulation types are below:

- λ of EPS = 0.030 W/(m.K)

- λ of mineral wool = 0.038 W/(m.K)

- λ of PIR board = 0.023 W/(m.K)

Question: ie stated 225 thick is 2.13 what is the value for 450 mm thick? how is this calculated ? thanks.

Hi Stephen, there is no hard and fast rule without measuring it with specialist equipment. What my colleagues demonstrated here is the journey from a pretty low base of an old building and the impact of the insulating materials – using simplification along the way. To get a better feel for these things, have a look at the research undertaken by Paul Baker, of the Glasgow Caledonian University on behalf of the Scottish Govt for old buildings. Has some great examples of thickness vs internal conditioning and gives detailed findings. Link here: http://www.historic-scotland.gov.uk/gd/largetext/paul_baker_thermal_performance_of_traditional_masonry_walls.pdf

Hope this helps.

Hello There

I want to extend my 1930’s style house. The existing wall is face brick outer skin, 50mm cavity, and brick inner skin with a 15mm hard plaster internal finish. The total wall thickness is approximately 270mm thick. Can you suggest a method of construction of this thickness which meets the Building Regs U-Value? I don’t want to have a “step” in the wall on the internal finish and I would rather not increase the thickness of the existing wall. Many thanks

Graham